Construction of a Structural Ventilation House

Structural Ventilation of the Building Envelope (aka Structural Ventilation) is best described at this link https://vacek.llc/structural-building-ventilation/.

The goals of the system are:

- Improve Indoor Air Quality by Ensuring Conditioned Filtered Outdoor Air Is Supplied for to the Structure for Improved Respiration and Controlled Room Temperature and Humidity

- Minimize Moisture, Contamination, and Deterioration of the Building Envelope by Allowing Air Exhausted from the Interior to Flow Through the Building Envelope

- Reduce Energy Costs by Allowing the Air Flow Through the Building Envelope to Minimize Thermal and Moisture Flow Between the Exterior and Interior

The Property

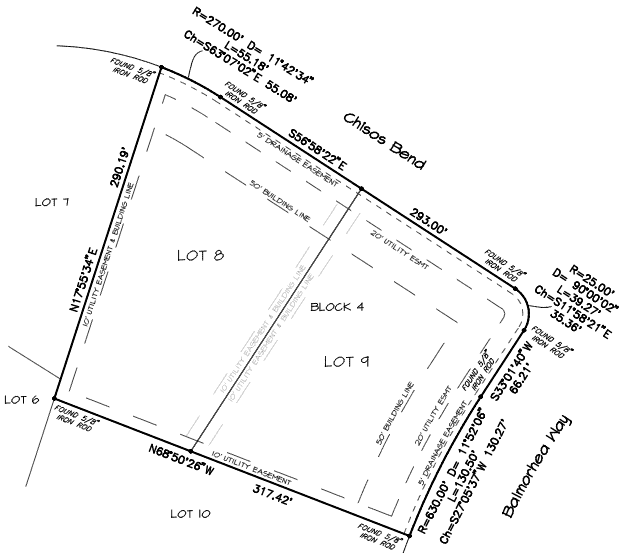

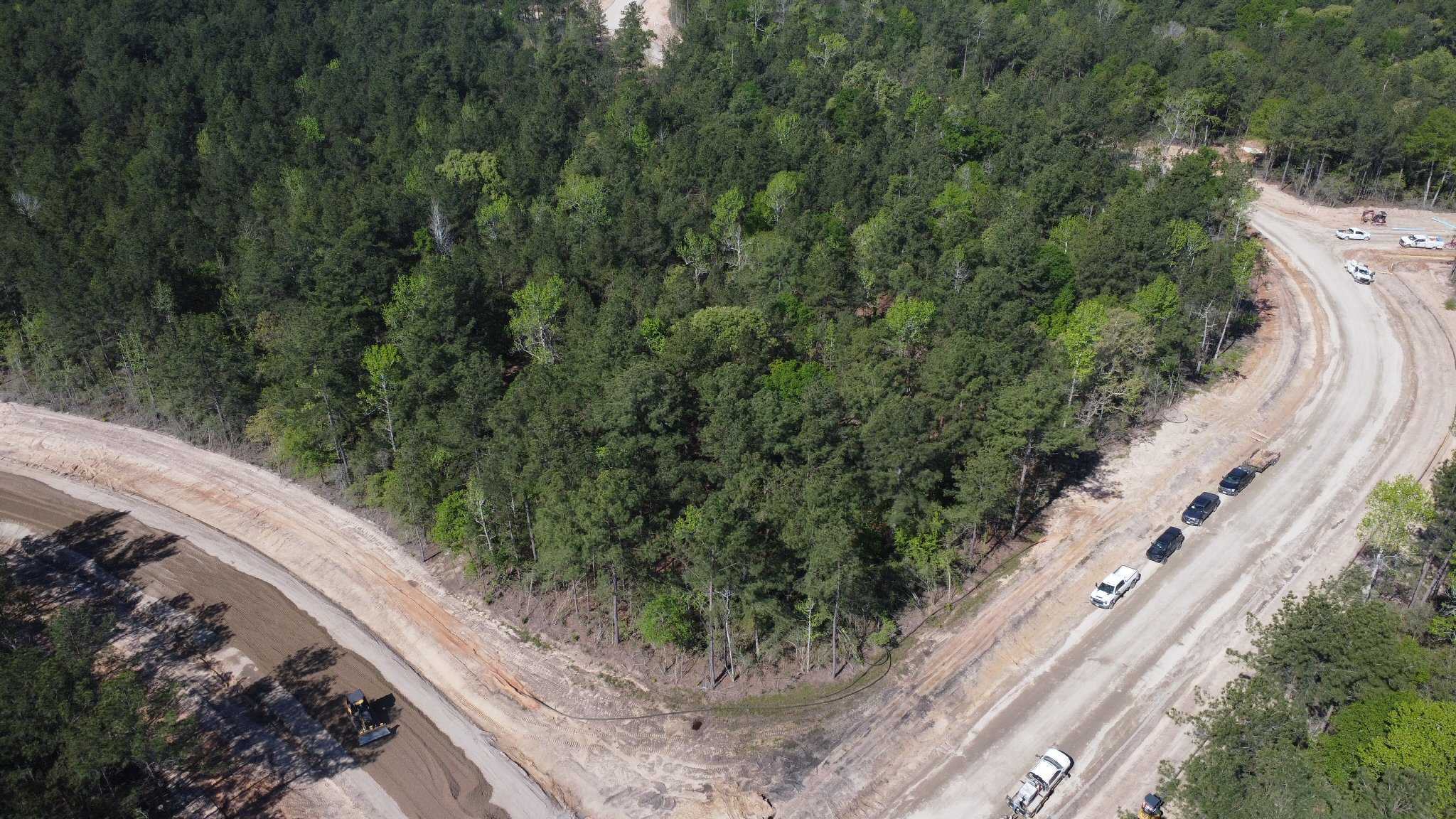

The property is located in Magnolia, Texas. The 2 acre corner lot is densely wooded with pines, oaks, and other tree varieties. Soils are sandy. The ground elevation is about 295 feet which is significantly higher than nearby Houston, which measures 50 feet Downtown. The property slopes downward towards the winding streets. The house will be positioned over the property line between Lots 8 and 9. The view east, west and north will be rooftops behind the parklike atmosphere.

Clearing the Site

We hydro-mulched the central area of the building site to have a better view of the property, but kept trees larger than 3ӯ. These hydro-mulch machines are incredible. They grind up brush and small trees without effort. I was told that hydro-mulching, as shown here, is a newer generation. The past generation had a tendency of overheating. The result is a brush cleared site with shredded debris covering the ground. A termite feast and a manicured building site.

Soil Sampling

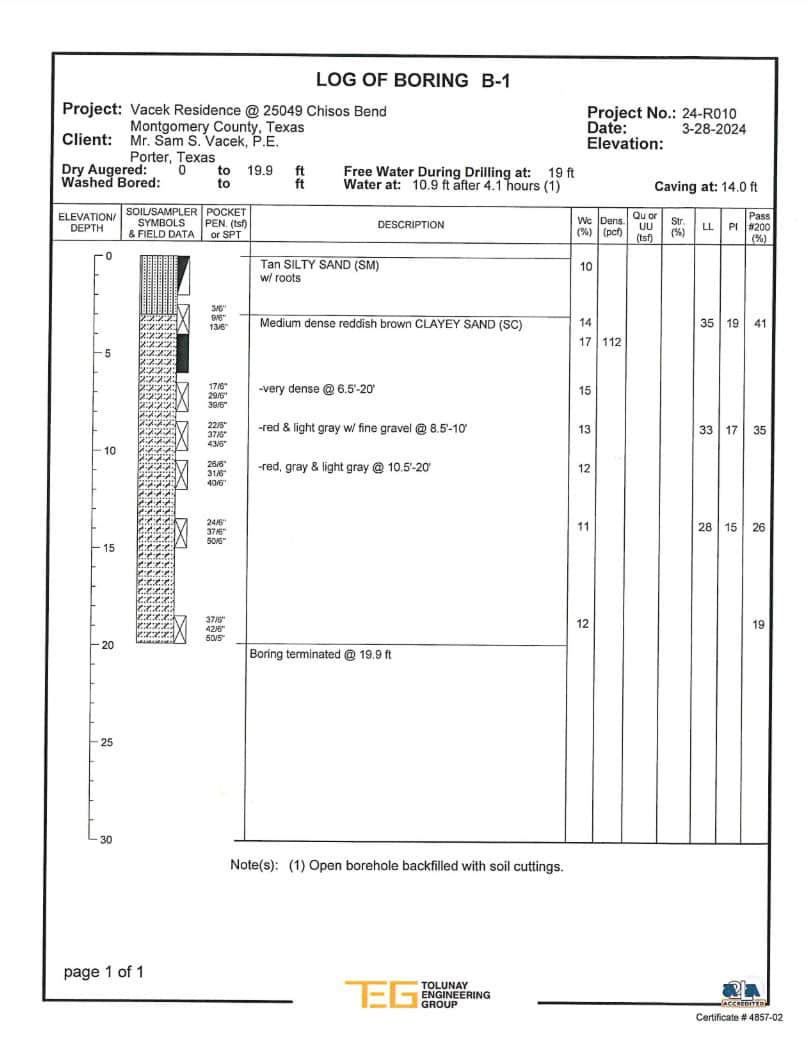

The soils were sampled at 3 locations to about the 20 foot depth. Representative ground elevations were taken at the boring locations and at the extremes of the expected house footprint. The equipment used to take the soil samples was a crawler on tracks that could maneuver between the trees. It was quite nimble. The crawler was equipped with an auger and a split spoon. A split spoon is a tube that is about 2”Ø and about 30” long. It is hammered into the ground using a specified weight dropped from a specified height above.

The name “split spoon” comes from the “split” of the tube along it’s length such that each side is semicircular. The number of hammer hits to move the split spoon down at 6” increments were recorded (blow counts). The greater the blow counts, the stronger the soils. 18” of soil was collected into each split spoon to the 20’ depth explored. The soil rolls out of the split spoon to be classified. The soils were typically a mixture of sand and clay. The deeper soils were stiff and dense. Each hole sampled took about 2 hours to complete. Samples were sealed and taken to the laboratory for testing.

Soils Testing and Results

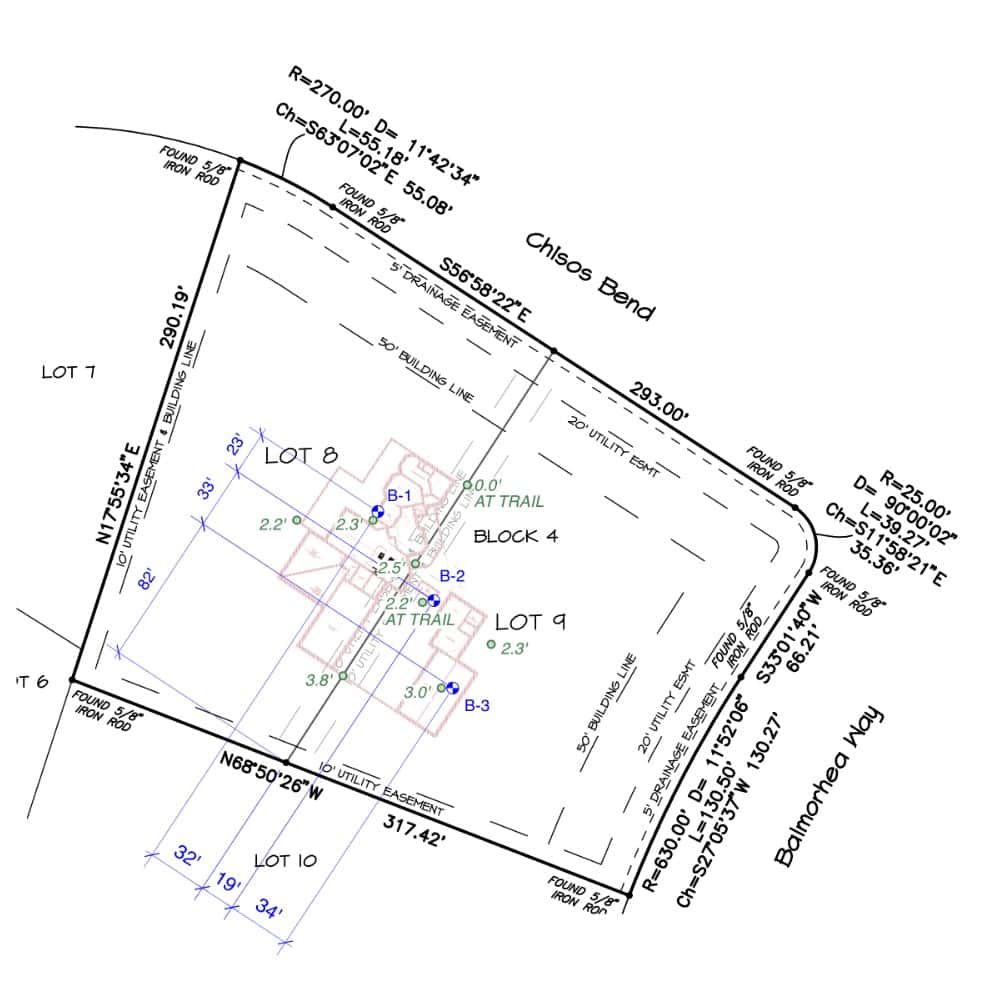

The three soil samples were obtained from the following locations. They were located at the future house; outlined in red. Ground elevations were taken at the boring locations and at the extents of the house. A 4 foot elevation change was measured between the front and rear of the house. The site slopes down 5 to 10 feet to the streets.

The samples were taken to the geotechnical engineer’s office for further testing.

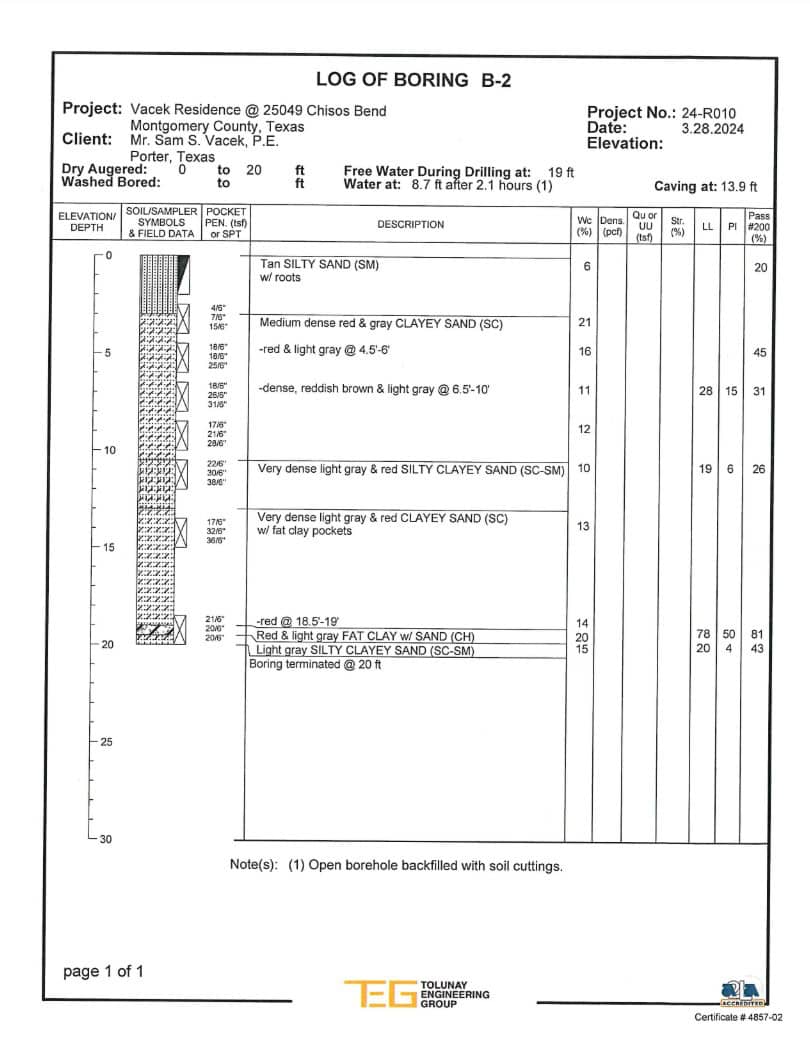

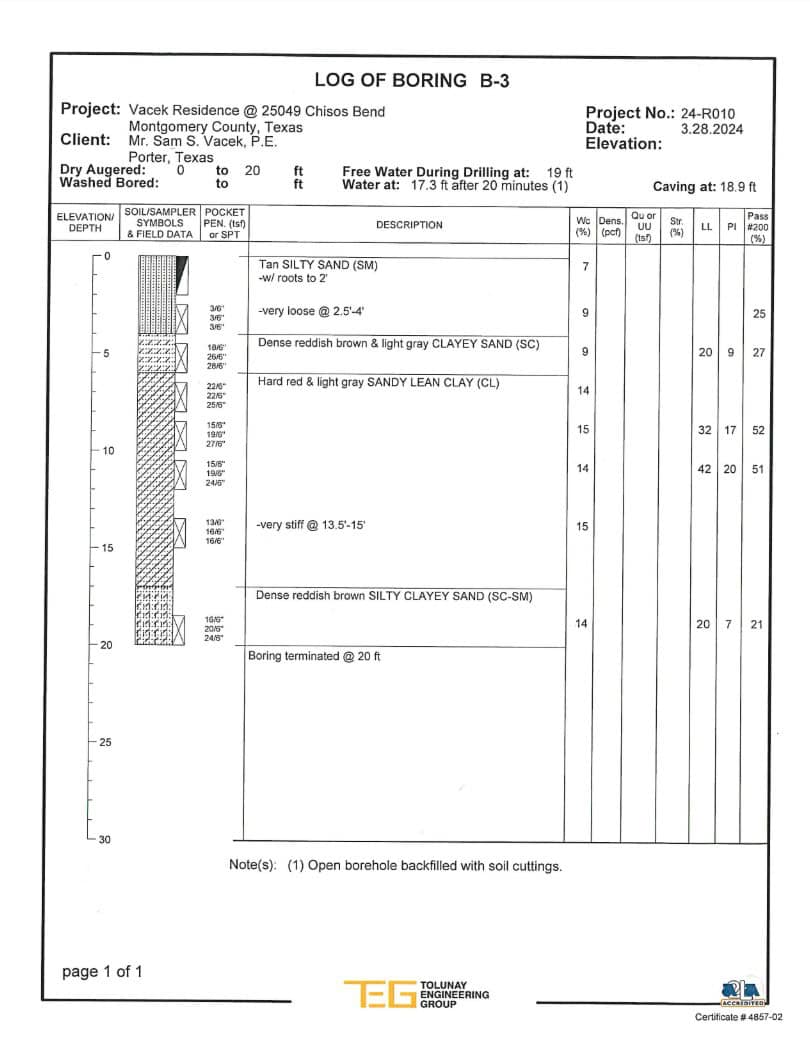

The following boring logs provide the results of the soil sampling with soil descriptions vs depth, groundwater depth, Standard Penetration Tests (SPT – blow count test results), and soil properties including water content, liquid limit (LL – moisture content when the soil is no longer plastic), and plasticity index (PI – the moisture content difference between soils in a dry state and the liquid limit.

The Standard Penetration Test, per Wikipedia, is described as follows:

The test uses a thick-walled sampling tube, with an outside diameter of 5.01 cm (2 in) and an inside diameter of 3.5 cm (1.375 in), and a length of at least 60 cm (24 in). The sampling tube is driven into the ground at the bottom of a borehole by blows from a hammer with a mass of 63.5 kg (140 lb) falling a distance of 75 cm (30 in). The sample tube is driven a total of 45 cm into the ground and the number of blows needed for the tube to penetrate each 15 cm (6 in) interval up to a depth of 45 cm (18 in) is recorded. The sum of the number of blows required for the second and third 15 cm (6 in) intervals of penetration is termed the “standard penetration resistance” or the “N-value”. N-value provides an indication of the density of the ground, and it is used in many empirical geotechnical engineering formulae.

The test may be stopped if any of the following conditions are met: (1) a total of 50 blows have been applied in any one of the 15 cm (6 in) intervals, (2) a total of 100 blows have been applied over the total 45 cm (18 in) depth, or (3) there is no observed advance of the sampling tube during 10 successive blows.:

In simpler terms, the SPT is a good test to determine how strong the soils are.

The liquid limit (LL) and plasticity index (PI) are useful values. A PI of 20 or less is typically a stable, non-expansive soil. A PI between 20 and 35 is a moderately expansive soil while a PI greater than 35 is a highly expansive soil. If you review the 3 borings, the PI’s are typically 20 or less except at about the 19 foot depth of Boring B-2.

The PI of the fat clay at B-2 is 50 and LL is 78. The high LL means the soil can absorb more moisture and the higher PI means the soil can swell more and that the dry moisture content can be low since LL – PI = Plastic Limit or dry state of soil.

Overall, the soils are strong and stable below the silty sands.

Based upon this report, it has been determined that a slab on grade foundation is suitable with little risk. A conventionally reinforced concrete slab on grade is chosen and will be constructed of a 4.5” concrete slab cast monolithic with a grid of 12” x 30” concrete grade beams spaced 12 feet apart. The slab will be reinforced with #3 @ 12” o.c. each way or equivalent welded wire mesh.

Vacek LLC, formerly Vacek Group, is a Houston area structural and architectural engineering company established in 1994. The company offers years of experience to insurance companies, attorneys, architects and the private sector.

NAVIGATION